An epdm rubber gasket creates a reliable seal for many industrial and construction applications. You benefit from its impressive durability and flexibility, which help maintain sealing integrity even in extreme temperatures. When you select this material, you gain resistance to harsh chemicals and environmental factors. You also enjoy protection against UV rays, ozone, and weather, making it ideal for outdoor use. EPDM rubber gaskets offer watertight sealing and perform well under low to moderate pressure.

-

Key reasons for choosing EPDM rubber gaskets:

EPDM Rubber Gasket Overview

What Is EPDM?

You encounter EPDM in many industrial and commercial products. EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber with a unique chemical structure. Manufacturers create EPDM by polymerizing ethylene, propylene, and a small amount of diene monomer. This combination gives EPDM its outstanding flexibility, chemical stability, and weather resistance. The diene component allows for cross-linking during vulcanization, which significantly increases durability.

Note: The saturated polymer backbone of EPDM provides superior resistance to heat, sunlight, oxidation, and ozone. This makes it a preferred choice over unsaturated rubbers, especially for outdoor and high-stress environments.

You benefit from EPDM’s classification as an unsaturated polyolefin. This structure ensures that your gaskets maintain performance even when exposed to harsh conditions.

EPDM Rubber Gasket Uses

You will find epdm rubber gasket solutions in a wide range of industries. Their versatility and reliability make them essential for many sealing applications. Common uses include:

-

Automotive: Door seals, window seals, and under-the-hood components.

-

Construction: Flat roofing systems for both commercial and residential buildings.

-

Electrical: Insulation for high-voltage cables and power plants.

-

Plumbing: Sealing components such as faucet seals, pipe gaskets, and valves.

-

Expansion joints: Bridges and buildings use these gaskets to absorb movement.

-

Marine: Seals that require durability against environmental stress.

You choose epdm rubber gasket products for their exceptional resistance to UV exposure, ozone, and extreme temperatures. They also offer excellent noise-dampening properties and resist a wide range of chemicals and solvents.

Manufacturing Basics

You can expect a precise and controlled process when producing epdm rubber gasket components. The main steps include:

-

Material Preparation: Technicians formulate EPDM rubber compounds by mixing raw rubber, curing agents, carbon black, and other additives.

-

Mixing and Compounding: The raw materials blend under controlled temperature to create a homogenous compound.

-

Molding: The compound is shaped into the desired gasket profile using compression molding.

-

Curing (Vulcanization): The molded EPDM undergoes heat and pressure to cross-link the rubber molecules, transforming it into a thermoset elastomer.

-

Finishing and Quality Control: The cured gaskets are trimmed, inspected for dimensional accuracy, and tested for performance.

Tip: Quality control measures include raw material inspection, precise mixing, high-precision molding, and thorough performance testing. You can rely on these steps to ensure that each gasket meets strict industry standards.

You gain confidence in the reliability and consistency of epdm rubber gasket products because manufacturers implement rigorous quality checks at every stage.

Key Properties

Weather & Ozone Resistance

You need a gasket material that stands up to harsh outdoor conditions. EPDM rubber gaskets deliver outstanding weather and ozone resistance. This property ensures that your seals do not crack, fade, or lose flexibility when exposed to sunlight, rain, or fluctuating temperatures. When you compare EPDM to other common gasket materials, you see a clear advantage:

|

Material |

Weather Resistance |

|---|---|

|

EPDM Rubber |

Excellent; UV and ozone resistant |

|

Natural Rubber |

Poor; prone to cracking under UV exposure |

UV Protection

You can rely on EPDM rubber gaskets for superior UV protection. The unique chemical structure of EPDM resists the damaging effects of ultraviolet rays. This means your seals maintain their integrity and performance, even after years of direct sunlight. You avoid premature aging and costly replacements because EPDM does not degrade like natural rubber or many other elastomers.

Longevity

When you choose EPDM rubber gaskets, you invest in long-term performance. These gaskets can last for decades in outdoor environments. Consider these typical service lifespans:

-

EPDM rubber gaskets can have an estimated shelf life of up to 15 years depending on the application.

-

They can remain functional for decades.

-

One study indicated that EPDM roofing had a minimum age of 30 years and a possible service life of more than 50 years.

You reduce maintenance costs and downtime because EPDM maintains its sealing properties over time.

Temperature Tolerance

You face temperature extremes in many industrial and construction settings. EPDM rubber gaskets perform reliably across a wide range of temperatures. You can use them in both hot and cold environments without worrying about loss of flexibility or sealing ability.

|

Service Type |

Temperature Range |

|---|---|

|

Long-term |

-50°C to +150°C |

|

Short-term |

-65°C to +200°C |

You benefit from this broad temperature tolerance, which covers most real-world applications. Typical temperature ranges for EPDM rubber gaskets are -40°F to 250°F (-40°C to 120°C), with some formulations handling even more extreme conditions.

Extreme Conditions

You should know that EPDM rubber is sensitive to rapid temperature changes. Sudden shifts from hot to cold can create stress concentrations and may lead to damage. To preserve the integrity of your seals, you should transition gradually between temperature extremes. This practice helps you maintain the long-term performance of your EPDM rubber gaskets.

Chemical Resistance

You often need a gasket that resists a variety of chemicals. EPDM rubber gaskets excel in this area, especially when exposed to acids, alkalies, and oxygenated solvents. You can use them in environments where other materials might fail.

|

Chemicals EPDM is Resistant To |

Chemicals That Can Degrade EPDM |

|---|---|

|

Acids and corrosive materials |

Oils (petroleum-based) |

|

Alkalies |

Aromatic hydrocarbons (benzene, toluene) |

|

Oxygenated solvents |

Chlorinated solvents |

|

Alcohols |

|

|

Acetones |

|

|

Ketones |

|

|

Esters |

|

Common Chemicals

You can trust EPDM rubber gaskets to withstand exposure to many common chemicals, including:

-

Acetic acid (glacial acetic acid)

-

Acetone (dimethyl ketone)

-

Ethanol (100%)

-

Ethylene glycol

-

Formaldehyde (10%)

-

Fluoric acid (50%)

However, you should avoid using EPDM in contact with petroleum-based oils, aromatic hydrocarbons, or chlorinated solvents, as these can degrade the material.

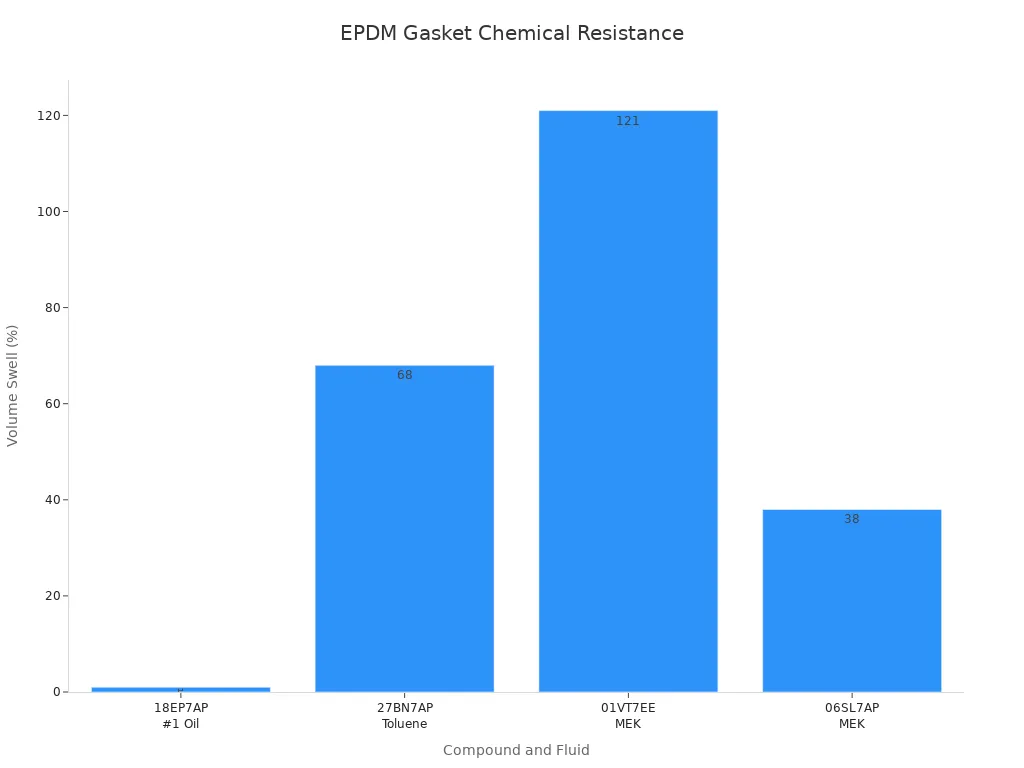

Laboratory tests confirm the chemical resistance of EPDM rubber. For example, EPDM compounds show minimal volume swell in many fluids, but significant swelling in aromatic and chlorinated solvents.

You can see that EPDM maintains its shape and sealing ability in most chemical environments, making it a reliable choice for demanding applications.

Flexibility & Compressibility

You need a gasket that adapts to irregular surfaces and maintains a reliable seal under compression. EPDM rubber gaskets provide good flexibility and compressibility, which allow you to achieve consistent sealing performance in a wide range of applications. This flexibility helps you install gaskets easily, even in tight or uneven spaces.

When you compare flexibility among common gasket materials, you see that EPDM offers a balanced profile. It is less flexible than silicone but more adaptable than neoprene. This balance gives you a material that resists permanent deformation while still conforming to surface variations.

|

Material |

Flexibility |

|---|---|

|

Silicone |

Excellent |

|

EPDM |

Good |

|

Neoprene |

Fair |

You can rely on EPDM rubber gaskets to compress under load and recover their shape when the pressure is released. This property ensures that your seals remain effective, even after repeated cycles of compression and relaxation.

Recovery Ability

You want your gasket to return to its original shape after compression. EPDM rubber gaskets excel in recovery ability, which means they maintain their sealing force over time. The compression set index for EPDM may overestimate deterioration, but in practice, these gaskets often perform better than expected. Hardening during use can actually improve sealing in some cases, so you benefit from a longer service life and reduced maintenance.

Tip: Always consider the actual application environment. EPDM rubber gaskets may show a 54.1% overestimation in design water pressure if you rely only on the compression set index. Real-world performance often exceeds laboratory predictions.

Watertight Sealing

You require a gasket that prevents leaks and maintains a watertight seal under pressure. EPDM rubber gaskets deliver outstanding sealing performance, making them a preferred choice for plumbing, roofing, and industrial applications. Their unique material structure allows them to conform to mating surfaces and block water ingress, even under fluctuating loads.

To ensure watertight sealing, manufacturers use several test methods:

-

Compression Set Testing: Checks the gasket’s ability to retain its shape after compression.

-

Hardness Testing (Shore A): Measures the hardness, which affects flexibility and sealing.

-

Tensile Strength and Elongation: Evaluates how much force the gasket can withstand and how far it can stretch.

-

Thermal Aging: Assesses long-term performance at high temperatures.

-

Chemical Resistance: Determines how well the gasket resists degradation from chemicals.

-

Leakage and Pressure Testing: Confirms the gasket’s ability to prevent leaks under different pressures.

You may also encounter joint waterproof tests, which simulate real-world conditions to evaluate the waterproof performance of EPDM gaskets. Advanced modeling tools, such as numerical simulation software and Python, help engineers analyze factors like joint deformation and material characteristics. These methods ensure that your epdm rubber gasket will perform reliably in demanding environments.

Note: Consistent watertight sealing reduces the risk of water damage, system failure, and costly repairs. You gain peace of mind knowing your systems are protected.

Material Comparison

EPDM vs Neoprene

When you compare EPDM and neoprene gaskets, you notice distinct differences in performance and cost. EPDM rubber gaskets excel in outdoor environments. You benefit from their high resistance to weather, UV rays, and ozone. Neoprene offers moderate resistance but tends to degrade faster when exposed to sunlight and harsh weather.

You should consider the following comparison table to help you choose the right material for your application:

|

Feature |

EPDM Rubber Gaskets |

Neoprene Gaskets |

|---|---|---|

|

Weather and UV Resistance |

Highly resistant, ideal for outdoor use |

Moderate resistance, degrades faster |

|

Water and Steam Resistance |

Superior waterproofing and steam resistance |

Decent water resistance |

|

Oil and Chemical Resistance |

Poor resistance to oils and petroleum |

Highly resistant to oils and chemicals |

|

Temperature Tolerance |

-40°C to 120°C |

-20°C to 100°C |

|

Flexibility and Durability |

High flexibility and long lifespan |

Flexible but may harden over time |

|

Cost Considerations |

Generally more affordable |

Can be more expensive |

You save money with EPDM because it is generally less expensive than neoprene for the same size and shape. EPDM suits cost-sensitive applications where oil resistance is not required. Neoprene’s higher cost comes from more expensive ingredients and lower production quantities.

Tip: Choose EPDM for outdoor, water, and steam applications. Select neoprene if you need oil and chemical resistance.

EPDM vs Nitrile

You encounter nitrile rubber gaskets in automotive, marine, and aerospace industries. Nitrile stands out for its resistance to oils, fuels, and petroleum-based fluids. EPDM rubber gaskets, on the other hand, offer superior performance in environments with steam, ozone, and sunlight.

Review this table to understand the differences:

|

Feature |

EPDM Rubber Gaskets |

Nitrile Rubber Gaskets |

|---|---|---|

|

Temperature Range |

-50 °C to +150 °C |

-25 °C to +100 °C |

|

Ozone and Sunlight Resistance |

Excellent |

Poor |

|

Compression Set Resistance |

Good |

Good |

|

Tear and Abrasion Resistance |

Excellent |

Good |

|

Steam Resistance |

Excellent |

Poor |

|

Resistance to Fuels and Oils |

Poor (not suitable for petroleum-based fuels) |

Good (resistant to gasoline, diesel, oils) |

|

Applications |

Industrial (steam lines, brake systems) |

Automotive, marine, aerospace |

You should select EPDM for applications that demand ozone, steam, and sunlight resistance. Nitrile works best where oil and fuel resistance are critical.

EPDM vs Silicone

You often face a choice between EPDM and silicone for gasket applications. EPDM performs exceptionally well in outdoor and plumbing environments. You benefit from its resistance to heat, cold, ozone, steam, electricity, UV rays, abrasion, and water. EPDM is ideal for roofing, plumbing, HVAC systems, and seals for windows and doors in vehicles.

-

EPDM provides excellent water resistance, making it a top choice for plumbing.

-

You prefer EPDM in harsh outdoor conditions where abrasion and weather resistance matter.

-

EPDM rubber gasket offers reliable sealing in environments with fluctuating temperatures and exposure to sunlight.

Silicone gaskets excel in high-temperature applications and provide superior flexibility. However, you may find EPDM more cost-effective and durable for outdoor and water-related uses.

Note: Choose EPDM for environments where water, abrasion, and weather resistance are essential. Opt for silicone when you need extreme temperature tolerance and flexibility.

Choosing EPDM Rubber Gasket

Selecting the right epdm rubber gasket for your application requires careful evaluation of several factors. You want to ensure optimal performance, long service life, and safety. The following criteria will help you make an informed decision:

-

Material Properties

Start by assessing the durometer, or hardness, of the gasket. The durometer affects how well the gasket seals under compression. Softer gaskets conform better to uneven surfaces, while harder gaskets provide greater resistance to extrusion. You should match the hardness to the specific demands of your sealing environment. -

Temperature Range

Review the temperature limits of the gasket. You need to confirm that the gasket can handle both the minimum and maximum temperatures it will experience. If your system operates in extreme cold or heat, select a formulation designed for those conditions. This step prevents premature failure and ensures consistent sealing. -

Chemical Compatibility

Examine the chemicals that the gasket will contact. EPDM rubber resists many acids, alkalis, and oxygenated solvents, but it does not tolerate petroleum-based oils or aromatic hydrocarbons. You should check compatibility charts or consult with suppliers to avoid material degradation. -

Pressure Rating

Determine the maximum pressure your system will generate. Choose a gasket with a pressure rating that exceeds this value. This precaution helps you avoid leaks and blowouts, especially in high-pressure applications. -

Surface Preparation

Prepare the mating surfaces before installation. Clean and dry surfaces allow the gasket to form a tight seal. Remove any oil, dust, or debris that could interfere with compression. Proper preparation reduces the risk of leaks and extends the life of the gasket.

Tip: Always consult with your supplier or manufacturer if you have unique requirements. They can recommend custom formulations or profiles to match your application.

You should also consider the installation environment, expected maintenance intervals, and any industry-specific standards. By following these steps, you ensure that your epdm rubber gasket delivers reliable performance and protects your equipment from leaks and damage.

Applications

Automotive

You rely on EPDM rubber gaskets for many automotive components because they deliver consistent performance and durability. In your vehicle, these gaskets serve as essential seals that keep out water, dust, and noise. You find them in a variety of parts, including:

-

Door seals

-

Window seals

-

Trunk seals

-

Hood seals

-

Radiator and heater hoses

-

Cooling system circuit hoses

-

Oil coolers

You benefit from the flexibility and heat resistance of EPDM rubber in these applications. The material adapts to complex shapes and maintains its properties under the high temperatures found in engine compartments. You also gain oil resistance in certain formulations, which helps protect critical systems. When you choose EPDM rubber gaskets for automotive use, you ensure long-lasting seals that withstand harsh road and weather conditions.

HVAC & Plumbing

You depend on EPDM rubber gaskets to maintain the reliability of HVAC and plumbing systems. These gaskets prevent leaks and help your systems maintain stable pressure. You can see the impact of EPDM properties in the following table:

|

Property |

Impact on HVAC and Plumbing Systems |

|---|---|

|

Excellent sealing |

Prevents leaks and maintains stable pressure |

|

Durability |

Ensures long-lasting performance under various conditions |

|

Environmental resistance |

Protects against moisture and UV, enhancing system reliability |

You notice that EPDM rubber performs well in harsh environments, including those with UV exposure and ozone. This makes it an ideal choice for outdoor HVAC units and plumbing installations. You also benefit from efficient operation, as the gaskets help maintain system integrity and reduce the risk of costly repairs.

Tip: Use EPDM rubber gaskets in HVAC and plumbing systems to prevent leaks and ensure efficient, long-term operation.

Construction

You see EPDM rubber gaskets used throughout the construction industry. These gaskets provide reliable sealing for windows, doors, curtain walls, and roofing systems. You gain several advantages when you select EPDM for construction projects. The table below highlights the primary benefits:

|

Benefit |

Description |

|---|---|

|

Cost-effectiveness |

EPDM rubber gaskets are known for being economical, reducing overall project costs. |

|

Weather resistance |

They resist heat, ozone, and various chemicals, making them suitable for outdoor and harsh conditions. |

|

Low maintenance requirements |

EPDM gaskets require minimal upkeep, saving time and resources over their lifespan. |

You also benefit from a long service life. With proper installation, EPDM gaskets can last over 30 years. They do not degrade from UV exposure, which means you avoid frequent replacements. You can trust EPDM rubber gaskets to deliver consistent performance and protect your building envelope from water and air infiltration.

Industrial & Electrical

You encounter EPDM rubber gaskets in a wide range of industrial and electrical applications. These gaskets play a critical role in protecting equipment, ensuring safety, and maintaining system performance. When you select EPDM for your industrial or electrical systems, you gain several advantages that help you meet demanding operational requirements.

In industrial environments, you often face exposure to moisture, dust, chemicals, and temperature fluctuations. EPDM rubber gaskets provide a reliable seal that keeps contaminants out of sensitive machinery. You can use them in pumps, compressors, valves, and pipe flanges. Their flexibility allows you to achieve a tight seal, even on uneven surfaces. This helps you prevent leaks and equipment failures, which can lead to costly downtime.

You also benefit from EPDM’s outstanding performance in electrical systems. The material’s unique properties make it ideal for insulating and protecting electrical components. Consider the following table, which highlights the key features that make EPDM rubber gaskets a top choice in these settings:

|

Property |

Explanation |

|---|---|

|

High Dielectric Strength |

EPDM gaskets can withstand electrical stress, preventing breakdown and ensuring effective insulation. |

|

Low Electrical Conductivity |

This property minimizes the risk of short circuits and electrical shocks in industrial settings. |

|

Sealing Capabilities |

They protect sensitive electrical components from moisture, dust, and contaminants, enhancing reliability. |

|

Overall Safety and Reliability |

Their properties ensure the safety and longevity of electrical systems in industrial applications. |

You rely on EPDM gaskets to insulate high-voltage equipment, such as switchgear, transformers, and circuit breakers. The high dielectric strength of EPDM prevents electrical breakdown, which helps you maintain safe and efficient operations. Low electrical conductivity further reduces the risk of short circuits and electrical shocks. This is especially important in environments where safety is a top priority.

Tip: Use EPDM rubber gaskets in control panels, junction boxes, and cable entry points to protect against moisture and dust. This simple step can extend the life of your electrical systems and reduce maintenance needs.

You also find EPDM gaskets in renewable energy installations, such as solar panels and wind turbines. Their resistance to weather, UV rays, and ozone ensures long-term performance, even in harsh outdoor conditions. By choosing EPDM, you help safeguard your equipment and support reliable energy production.

Advantages

Cost-Effectiveness

You gain significant savings when you choose EPDM rubber gaskets for your projects. Manufacturers produce EPDM at scale, which lowers material costs. You benefit from the long service life of EPDM, reducing the frequency of replacements. The durability of EPDM means you spend less on repairs and maintenance over time. You also avoid unexpected downtime because EPDM maintains its sealing properties in harsh environments. Many industries prefer EPDM for its balance of performance and affordability. You can select EPDM gaskets in standard or custom sizes without a major increase in cost. This flexibility helps you manage budgets and meet project requirements efficiently.

Tip: You can maximize cost savings by selecting EPDM gaskets with the right hardness and profile for your specific application. Proper selection prevents over-engineering and unnecessary expenses.

Environmental Benefits

You support sustainability when you use EPDM rubber gaskets. EPDM meets strict environmental and safety standards, which helps you comply with regulations and protect the environment. Many EPDM gaskets carry certifications that demonstrate their safety for people and ecosystems. You can review the following table to see common certifications and their significance:

|

Certification |

What It Means |

Where It’s Needed |

|---|---|---|

|

RoHS |

Free of hazardous heavy metals |

All EU electronics and components |

|

REACH |

Safe for human health and environment |

EU general goods |

|

FDA |

Food contact safe |

Food processing, kitchenware |

|

UL 94 |

Flame resistance |

Electrical housings, appliances |

|

WRAS / NSF-61 |

Safe for drinking water |

Potable water systems, plumbing |

You ensure compliance with local and international standards when you select EPDM gaskets with these certifications. EPDM rubber does not release harmful substances during use, which protects water supplies and air quality. You also reduce your environmental footprint because EPDM gaskets last longer and require fewer replacements. This longevity means less waste and lower resource consumption over the life of your equipment.

Maintenance

You extend the lifespan of EPDM rubber gaskets by following recommended maintenance practices. Proper care helps you avoid premature failure and costly repairs. You should store gaskets in a cool, dry, and dark location, away from sunlight, ozone, and heat sources. Avoid stacking or compressing gaskets in ways that deform their shape. Inspect gaskets periodically for cracks, brittleness, or other signs of aging. Ensure mating surfaces are clean, smooth, and free of damage during installation. Follow proper torque and tightening sequences to avoid over- or under-compression. Confirm that the gasket profile fits the joint and accommodates movement, vibration, or thermal expansion. Look for leaks, bulges, hardening, or cracks during inspections. Replace any gasket showing signs of damage, rather than waiting for failure.

-

Store rubber seals in a clean, dry environment away from chemical fumes or vapors.

-

Ensure proper installation by following the manufacturer’s guidelines and avoiding overstretching or twisting the seal.

-

Perform routine visual inspections to detect early signs of surface degradation, material swelling, or chemical attack.

-

Clean both the gasket and flange surfaces thoroughly using non-abrasive materials.

You maintain system reliability and safety by following these steps. Regular maintenance ensures that EPDM gaskets continue to provide effective sealing and protection throughout their service life.

Selection Factors

Application Needs

You must evaluate your specific application before selecting an EPDM rubber gasket. Each system has unique requirements, and the gasket must meet those demands. Consider the type of fluid or gas the gasket will seal. Review the pressure levels and mechanical stresses involved. If your system experiences frequent movement or vibration, choose a gasket profile that absorbs shock and maintains a tight seal. For plumbing, HVAC, or automotive uses, you need a gasket that resists water, steam, and fluctuating temperatures. In electrical assemblies, prioritize insulation and dielectric strength. Always match the gasket’s physical properties to your operational needs to ensure reliable performance.

Tip: Select a gasket thickness and hardness that fits your joint design. Thicker gaskets may offer better sealing but can require higher compression force.

Environmental Conditions

You face many environmental challenges in industrial and outdoor settings. EPDM rubber gaskets excel in all-weather performance. You benefit from their extreme resistance to outdoor conditions, including sunlight, ozone, and moisture. The material withstands a wide range of temperatures, making it suitable for both hot and cold climates. If your equipment operates outdoors, EPDM protects against UV degradation and cracking. In chemical plants or food processing, you need a gasket that resists exposure to cleaning agents and mild acids. EPDM maintains its properties even after years of exposure to harsh elements.

-

EPDM is known for its all-weather performance.

-

It has extreme resistance to outdoor conditions.

-

The material can withstand a wide range of temperatures.

Note: Additives can significantly affect the performance of EPDM rubber gaskets. You should understand how these additives interact with the rubber to ensure compatibility and longevity in your application.

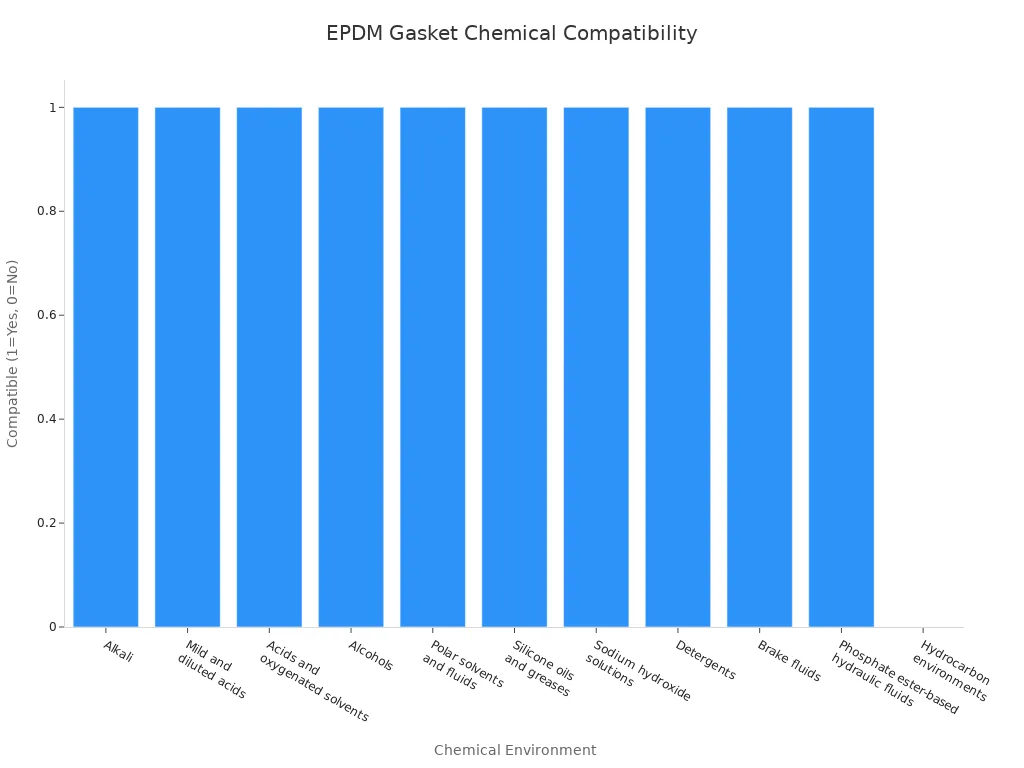

Material Compatibility

You must confirm that EPDM rubber gaskets are compatible with other materials in your assembly. Chemical compatibility prevents premature failure and ensures a long service life. EPDM works well with many fluids and chemicals, but it does not tolerate hydrocarbon environments. Review the table below to check compatibility with common substances:

|

Chemical Compatibility |

Description |

|---|---|

|

Alkali |

Compatible |

|

Mild and diluted acids |

Compatible |

|

Acids and oxygenated solvents |

Compatible |

|

Alcohols |

Compatible |

|

Polar solvents and fluids |

Compatible |

|

Silicone oils and greases |

Compatible |

|

Sodium hydroxide solutions |

Compatible |

|

Detergents |

Compatible |

|

Brake fluids |

Compatible |

|

Phosphate ester-based hydraulic fluids |

Compatible |

|

Hydrocarbon environments |

Incompatible |

You should avoid using EPDM gaskets with petroleum-based oils or hydrocarbon fluids. For assemblies exposed to these substances, select a different gasket material. Always consult compatibility charts and supplier recommendations before installation. This step helps you prevent leaks, swelling, and material breakdown.

Tip: Test EPDM gaskets with your specific fluids and materials before full-scale use. Early testing helps you identify any potential issues and ensures a reliable seal.

Limitations

EPDM Rubber Gasket Drawbacks

You should understand the limitations of EPDM rubber gaskets before making a selection. While EPDM offers many advantages, it also presents several drawbacks that can affect performance in specific environments. The table below summarizes the most significant issues you may encounter:

|

Drawback |

Explanation |

|---|---|

|

Poor compatibility with petroleum products |

EPDM rubber does not perform well with oils, gasoline, and kerosene. Exposure leads to swelling and degradation, which can cause leaks and mechanical failures in machines. |

|

Inadequate performance at high temperatures |

EPDM withstands temperatures up to 150°C. Beyond this point, the material becomes brittle and cracks, requiring frequent replacements in high-heat environments. |

|

Limited resistance to chemicals |

EPDM is susceptible to damage from certain acids, alkalis, and solvents. This vulnerability can result in loss of structural integrity, making EPDM unsuitable for chemical processing applications. |

|

Low tensile strength and tear resistance |

EPDM rubber can stretch and tear under mechanical stress. You may experience increased maintenance and downtime in dynamic sealing applications. |

|

Poor adhesion to metals |

EPDM does not bond well to metal surfaces. This poor adhesion can lead to separation or leakage in applications that require rubber-to-metal bonding, complicating manufacturing and increasing costs. |

|

Limited use in food and pharmaceutical industries |

EPDM can leach chemicals, posing contamination risks in environments where hygiene is critical. You should avoid EPDM in food processing or medical device manufacturing. |

Note: You must evaluate these drawbacks against your application requirements. Ignoring them can lead to premature gasket failure, increased maintenance costs, and safety risks.

When Not to Use EPDM

You should avoid EPDM rubber gaskets in certain scenarios. Alternative materials may offer better performance and safety. The following table highlights common situations where EPDM is not the best choice and suggests suitable substitutes:

|

Alternative Material |

Key Properties |

|---|---|

|

Nitrile rubber (NBR) |

Resistant to oils, fuels, and chemicals. You should use NBR for automotive and industrial applications where exposure to petroleum products is frequent. |

|

Neoprene |

Good resistance to oils, ozone, and weathering. Neoprene works well in environments with moderate oil exposure and outdoor conditions, but it has limited high-temperature performance. |

|

Silicone |

Best for high-temperature and food-grade applications. Silicone resists extreme heat and meets hygiene standards, making it ideal for food processing and medical devices. It costs more and offers limited abrasion resistance. |

You should select nitrile rubber when your system handles oils, fuels, or chemicals. Neoprene suits outdoor applications with moderate oil exposure. Silicone provides superior performance in high-temperature or hygienic environments. By choosing the right material, you protect your equipment and ensure reliable operation.

⚠️ Tip: Always match the gasket material to your operating environment. You reduce the risk of leaks, contamination, and costly downtime by selecting the most compatible option.

You gain reliable sealing, weather resistance, and long service life when you choose EPDM rubber gaskets. These gaskets perform well in demanding environments and offer cost-effective solutions for many industries. You should consider EPDM’s unique properties for your next project. If you have special requirements, consult with a gasket specialist or review technical data to ensure the best fit.

For complex applications, always seek expert advice to maximize performance and safety.